| Contact Us |

| Home |

| Pump Parts & Manufacturers List |

| Testimonials |

| About Us |

| Linecard |

| Agitators & Mixers |

| Air Compressor & Vacuum Process Systems |

| Accessories |

| Brewery Equipment |

| Chemical Feed Systems |

| Heat Transfer Products |

| Heat Exchangers & Tube Bundles |

| Sample Coolers |

| Macerators |

| Pulsation Dampeners |

| Pumps & Accessories |

| Pump Repairs & Parts |

| Separators |

| Shear Blenders & Pumps |

| Tanks |

Sales & Service Locations: Austin, TX Corporate Offices: 1170 Tree Swallow Drive |

Neptune Sample Coolers

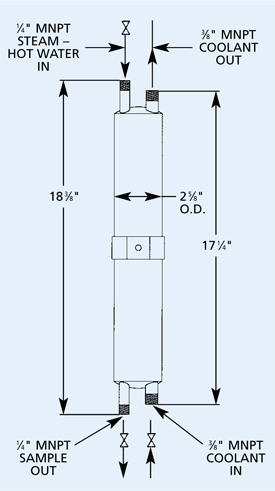

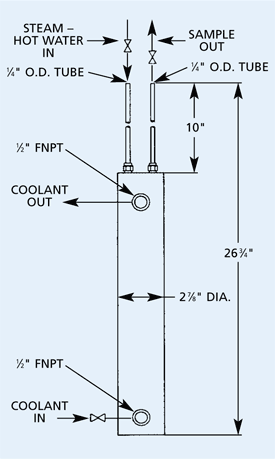

Neptune Sample Coolers are purpose-built for cooling hot water or steam samples for easy handling and effective sample collection. These sample coolers are suitable for use on hot water, saturated steam, or superheated steam services, and is also available in a cleanable configuration. Standard Sample Cooler (SC-316 & SC-600) Features:

Cleanable Sample Cooler (SC-100) Extra Features:

Neptune Sample Cooler Specifications

* Maximum Operating Temperature: 750°F (400°C). Sample Cooler Performance: Assuming a coolant inlet of approximately 55°F (12°C) and exit of approximately 120°F (50°C), and a sample exit of approximately 110°F (43°C), the cooler will provide performance approximately per the ranges described below. Hot Water Samples:

Saturated Steam Vapor: The sample inlet and exit valves can be used to create various operating pressures in the cooler for producing samples from saturated steam vapor.

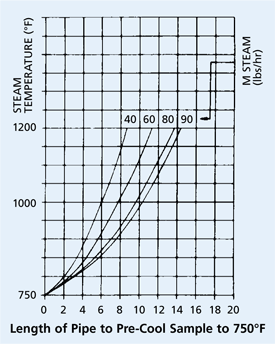

Superheated Steam: Maximum sample inlet temperature of 750°F (400°C).

Sample Cooler Installation: Proper installation requires valves on sample inlet and cooling water inlet for hot water service. An additional valve must be installed on the sample outlet for all vapor or steam services to obtain required operating pressures in the coil. Proper installation in superheated steam service also requires precooling the sample to 750°F (400°C), the maximum design operating temperature of the Neptune Sample Cooler. Precooling can be accomplished by installing a pipe between the main steam header and the sample cooler to radiate excess heat. The length of the pipe is determined from the chart at left. | |||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||