| Contact Us |

| Home |

| Pump Parts & Manufacturers List |

| Testimonials |

| About Us |

| Linecard |

| Agitators & Mixers |

| Air Compressor & Vacuum Process Systems |

| Accessories |

| Brewery Equipment |

| Chemical Feed Systems |

| Heat Transfer Products |

| Macerators |

| Dorr-Oliver Gorators |

| 6X4X10 Gorator |

| 4X3X8 Gorator |

| 4X4PP Gorator |

| Pulsation Dampeners |

| Pumps & Accessories |

| Pump Repairs & Parts |

| Separators |

| Shear Blenders & Pumps |

| Tanks |

Sales & Service Locations: Austin, TX Corporate Offices: 1170 Tree Swallow Drive |

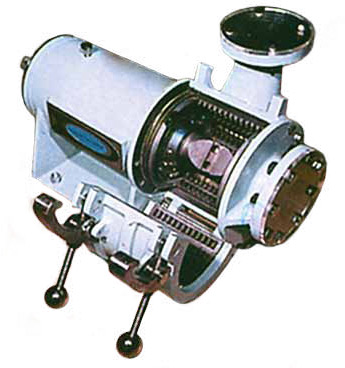

Dorr-Oliver 4X3X8 Gorator Macerator Pump

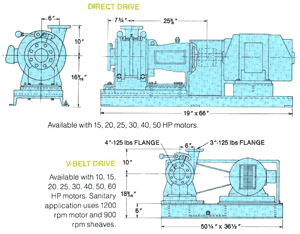

Built to Survive Sludge & Scum The 4x3x8 Gorator is designed and built for survival under tough sludge screening and scum and sludge disintegration service. Size reduction and disintegration is a back-breaking test for any sludge grinder, but this machine has been specifically designed to stand up to and handle this rough service. It is the most cost effective unit of its type on the market, offering savings in wear, maintenance and power use. To make it more durable, especially with the presence of grit residue, the new Gorator uses tool steel for the liner bars. And to reduce wear and power consumption, it operates at a low speed – 900 RPM. Current municipal wastewater treatment applications of the Gorator include sludge, scum, screenings and liquid waste disintegration. The 4X3X8 Gorator also features a large diameter, short overhang shaft for minimal deflection under shock loads. 6X4X10 Gorator Specifications: Casing & Flange Construction: Cast iron Rotor Plate Construction: Hardened steel Liner Bar Construction: Investment-cast 17-4 PH stainless steel or CD2 tool steel End Ring Construction: WS Meehanite Seal Assembly: Double mechanical seal standard Rotor: 8" diameter impeller Liner Bars: Discharge openings can be varied with combinations of standard parts Inlet Diamater: 4" Outlet Diameter: 3" Horsepower: up to 60HP @ 1800 RPM Drive Belt: 870 RPM V-belt drive is standard for abrasive wastewater applications |

|

|