| Contact Us |

| Home |

| Pump Parts & Manufacturers List |

| Testimonials |

| About Us |

| Linecard |

| Agitators & Mixers |

| Air Compressor & Vacuum Process Systems |

| Oil-less Reciprocating Air Compressors |

| Oil-less Reciprocating Air Systems |

| Oil-less Scroll Air Compressors |

| Oil-less Scroll Air Systems |

| Rotary Claw Vacuum Pumps |

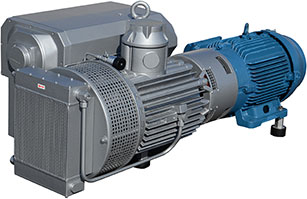

| Rotary Vane Vacuum Pumps |

| ¾ – 7½ HP Pumps |

| 10 – 25 HP Pumps |

| Dry Vacuum Pumps |

| Squire Cogswell Pumps |

| Air & Vacuum Pump Repair |

| Accessories |

| Brewery Equipment |

| Chemical Feed Systems |

| Heat Transfer Products |

| Macerators |

| Pulsation Dampeners |

| Pumps & Accessories |

| Pump Repairs & Parts |

| Separators |

| Shear Blenders & Pumps |

| Tanks |

Sales & Service Locations: Austin, TX Corporate Offices: 1170 Tree Swallow Drive |

Ohio Medical Rotary Vane Vacuum PumpsOhio Medical's rotary vane vacuum pumps are used in industrial and medical applications. Rotary vane vacuum pumps are positive-displacement pumps containing an impeller with vanes. This impeller is driven by an induction motor and is offset from the center of the cylindrical body of the pump. The offset means the vanes are closer to the top of the pump's body and farthest away from the body's bottom. The eccentrically-installed vanes divide the working chamber into two compartments with variable volumes. As the impeller turns, air flows into the enlarging suction chamber until it is sealed by the second vane. As the impeller continues to turn and decreases volume, the enclosed air is compressed en route to the outlet valve. The outlet valve is usually oil-sealed. When the valve opens, a trace of pump oil (a.k.a. operating fluid) enters the suction chamber, lubricates moving parts, seals the vanes against the pump's body, and ensures an optimal temperature balance through heat transfer. However, Ohio Medical also offers oil-less, dry-running rotary vane vacuum pumps, for applications where even traces of pump oil are unacceptable.

|

|

|