|

|

ODS Air-Operated Single Diaphragm Pumps

The Dorr-Oliver ODS is an air-operated single diaphragm pump. Because it is a diaphragm pump, it is superior to centrifugal and helical screw pumps for heavy-duty performance. And because it is air-operated, the ODS is significantly superior to mechanically or hydraulically operated models due to its simplicity of control and even power distribution.

The ODS pump is designed and built for long-term heavy-duty performance, year after year. It weighs two to three times more than many comparable air-operated double-diaphragm pumps, lasts far longer, and pumps slurries that no other unit can handle. The ODS really doesn't have an equal!

Contact us to learn how your process can benefit from ODS pumps.

The ODS air-operated single diaphragm pump will efficiently transfer anything that moves through a pipe, such as:

- Delicate crystal slurries

- Highly concentrated and unusually viscous slurries

- Highly abrasive slurries

- Highly corrosive slurries

- Very large solids in slurries

- Extremely volatile slurries

- Delicate and unstable slurries

- Air-entrained slurries

- Shear-sensitive slurries

Pulse Transfer Thickening: Another ODS Pump Advantage

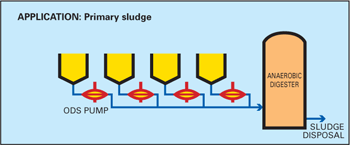

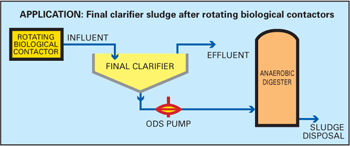

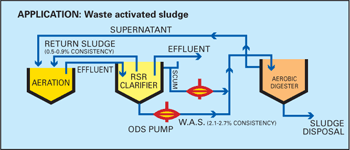

Besides all its other qualities, the ODS pump does things to improve sludge handling that no other pump can do. It's called "constant peak-velocity pulse transfer thickening" – in other words, no matter how much the pumping rate is reduced, the ODS pump will continue to deliver constant peak scouring velocity. This effect ends dilution of most sludges, including municipal sewage, primary clarifier underflow, aerated biological wastes, digested sludges and so on.

ODS pumps provide constant pumping velocity at all pumping rates. Pumping rates are matched to sludge accumulation rates, which in turn improves the operation of all the processes in a line.

ODS Additional Features & Benefits:

- Can be automated to match capacity to process requirements for maximum process efficiency.

- Able to be operated dry indefinitely. Cannot air bind, has no stator to burn out and no seal to fail.

- Seal-less design makes contamination of process slurry or the environment from seal leaks impossible.

- Adjustable while in operation for maximum flexibility for both capacity and discharge pressure.

- Low maintenance – once installed, the ODS pump requires almost no attention.

- Can handle tough corrosives, abrasives, temperatures to 200°F and slurries containing up to 75% solids.

- Rhythmic plunger-type action minimizes particle degradation of even the most delicate materials.

- Operation is completely leak-proof.

| How the ODS Pump Works |

|

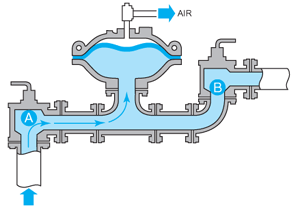

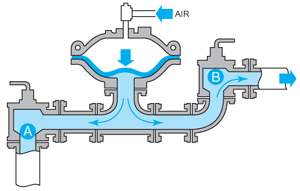

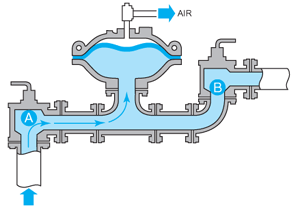

Fill Stroke

To fill the pump cavity, positive suction head (inlet pressure) is required. When inlet valve A is lifted by the pressure of the suction head, the slurry completely fills the pump cavity. The diaphragm returns to its normal convex position and the air exhausts. Discharge valve B, seated by line pressure, prevents slurry from returning to the pump cavity.

The minimum positive suction head required is 2 PSI above that at the level of the pump diaphragm centerline.

If suction lift is required, use the Spring-Assist or Air Cylinder-Assist models (shown below). |

|

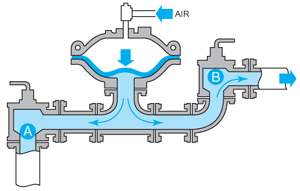

Discharge Stroke

Compressed air is admitted to the chamber above the diaphragm. The diaphragm descends, gradually increasing the pressure in the pump cavity. This in turn closes inlet valve A and causes discharge valve B to open when the line pressure is exceeded. Further movement of the diaphragm displaces the slurry from the pump cavity. The pumping action is positive, yet gentle so that delicate crystals and slurries can be transferred or metered without damage.

Electrical impulses from an adjustable timer alternately open and close the solenoid-controlled air valves which admit and exhaust air from the diaphragm cavity. |

| ODS Pump Variants |

|

|

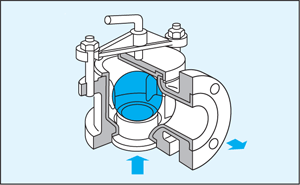

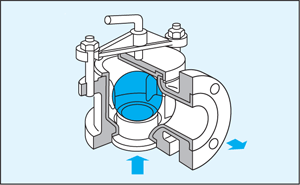

| Spring-Assist |

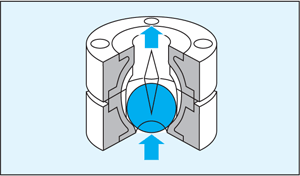

Air-Assist |

In this version, the diaphragm is mechanically lifted by a spring-actuated rod. The spring is cocked during the discharge cycle by the air pressure driving the diaphragm downwards. The discharge cycle is the same as the basic pump.

With this self-priming model:

- Suction lift is up to 10 feet.

- Normal capacity is increased up to 50% due to faster filling action.

- Slurries with high solids concentration and high viscosity can be handled.

|

In this version, the diaphragm is mechanically lifted by an air cylinder-actuated rod. At the top of the list stroke, the air is directed into the diaphragm chamber driving the slurry out of the pump cavity and simultaneously returning the air piston to the lower position.

With this model:

- Suction lift is up to 20 feet.

|

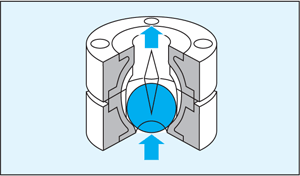

| Three Available Check Valves for ODS |

Type Q: Quick-opening ball-check valve This is the default valve supplied, unless another is specified, as it's a good all-around performer. A quick-opening yoke permits easier clean-out and inspection without breaking piping. Positive seating of the ball is assured by both gravity and guiding ribs. The ball seat is also replaceable. |

|

Type B: Inline ball-check valve This valve is highly efficient hydraulically, with flow passing straight through vertically. The inline ball check valve is best used in applications where maintenance is infrequent. Its streamlined internal design reduces the potential for material to clog or hang up. Positive seating of the ball is assured by gravity and line pressure. |

|

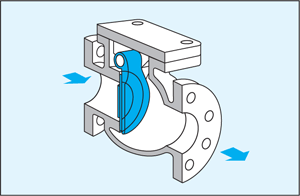

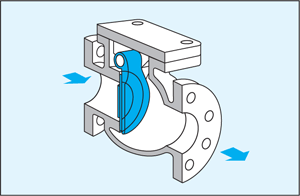

Type F: Flap-check valve This valve is perfect for applications needing to pass large, pipe-sized solids without clogging. The flap-check valve features a removable cover and flap, which allow for easier inspection and cleaning without breaking piping. A special elastomer disc is installed on the flap to ensure sealing, reduce noise and increase the life of the valve. Flow is straight through. |

|

|

|

Hours of Operation:

Monday – Friday, 8:30 a.m. – 5 p.m. EST

|

| |