|

|

|

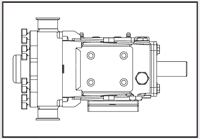

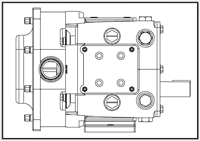

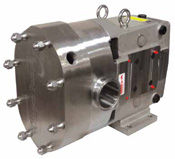

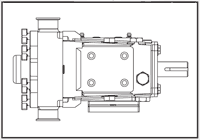

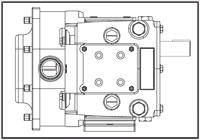

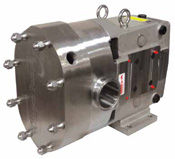

Ampco ZP1 and ZP2 Series Rotary Circumferential Piston Pumps

In this circumferential piston positive-displacement design, arc-shaped pistons travel in annular-shaped cylinders machined in the pump body. The resulting long sealing path reduces slippage and produces a smooth flow of product without destructive pulses or pressure peaks, and without valves or complex parts. Low-shear pumping action protects product from damage, and the low-slip operation provides excellent flow control and metering/filling capability. Santiary versions meet USDA and 3A sanitary standards.

The ZP1 and ZP2 Series rotary piston positive-displacement pumps are Ampco's newest. They are hydraulically and dimensionally interchangeable with other leading brands, and many common pump upgrades are included as standard. The most significant improvement is a 304 stainless steel gear case, standard on every ZP pump. The stainless gear case and all-stainless hardware provide high resistance to corrosion and compatibility with caustic agents – this eliminates rusting, chipping and peeling, and reduces harassment from plant inspectors!

The ZP1 series has been redesigned for easier maintenance and reduced downtime – click here to learn more about the ZP1+ Series.

Both ZP1 and ZP2 models can be rebuilt with oversized rotors to extend the pump's useful life. We offer several rebuild options – a complete rebuild, with new shafts, gears, bearings and rotors includes a one year factory warranty. Moreover, ZP1 pumps can be remanufactured as ZP1+ pumps.

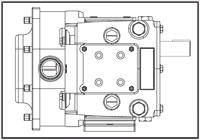

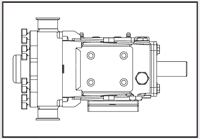

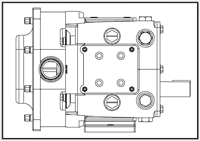

Mounting Options Side-Mount Left-Hand  Upper Mount  Side-Mount Right-Hand  Lower Mount

ZP Series Standard Features:

- Original Alloy 88 material rotors with nongalling appeal to maintain tight tolerances. Optional clearances available.

- Solid 316L stainless steel shafts on small pumps and 17-4PH on larger pumps, providing twice the tensile strength of 316L.

- Stainless steel bearing retainer prevents corrosion and enhances bearing protection.

- Tapered roller bearings to maintain axial forces for equal support in both directions

- Helical Timing Gears for increased load-carrying capacity and reduced noise.

- Separate oil chamber for gears using anti-microbial lube as standard.

- Sightglass oil plug.

- Gear housing designed to mount pump in four positions.

- Sealed cleanout plugs protect and extend bearing life.

- Threaded grease Zirks for easy replacement.

- Offering o-ring and mechanical seals to meet all your changing application needs.

- Pump housing in constructed of 316L stainless steel and machined and polished to conform with 3A standards.

- Cast solid 316L cover.

- Capacity Range: 0.1 to 310 gpm (0.02 to 70.4 m³/hr)

- Pressure Range: up to 500 psi / 34 bar

- Temperature Range: -40°F tp +300°F (-40°C to +150°C)

Note: Hot clearances required for high-temp operation

- Viscosity Range: 1 to 1,000,000 CPS

ZP2 Series pumps also feature inline cleanability

- Bakery: batters, dough, fats and oils, fruit filling, icing, oils, yeast

- Beverages: alcohol, wines and beer, wort, fruit concentrate, fruit juices, mash, soft drinks

- Candy: chocolate, cocoa butter, corn syrup, gelatin, sugars

- Canned Foods: baby food, jams, jellies, mayonnaise, potato salad, pudding, relish, stews

- Cosmetics: creams, emulsions, jellies, lotions, shampoo, toothpaste

- Dairy: butter, cream, curds, ice cream, margarine, milk, soft cheese, yogurt

- Dressings: mayonnaise, many other sauces

- Flavorings: concentrates, syrups

- Industrial: auto paint, inks, latex, polymers

- Meats: broth, fats, gelatin, pet foods, sausage fillings

Available Options:

|

|

|

| Rectangular Flange Inlet |

Jacketed Heating Cover |

Pressure Relief Valve |

| ZP Series & Competitors Comparison |

| Component |

Ampco Pumps |

Waukesha Cherry Burrell |

Wright Flow Technologies |

| Stainless Gear Case |

yes |

no |

no |

| Stainless Bearing Retainers |

yes |

no |

yes |

| 17-4PH H1150 Shafts |

yes |

no |

yes |

| Helical Gears |

yes |

no |

yes |

| 4-Way Mounting |

yes |

no |

yes |

| Multiple-Access Grease Fittings |

yes |

no |

yes |

| Threaded Grease Fittings |

yes |

no |

no |

| Solid Wave Spring |

yes |

no |

yes |

| Antimicrobial Lubricant |

yes |

no |

yes |

| 6 Oil Fill Plugs |

yes |

yes |

no |

| Oil Sight Glass |

yes |

yes |

no |

| Gasketed Clean-Out Plugs |

yes |

no |

no |

| ZP1 Pump Performance |

| Model |

Nominal Capacity |

Displacement |

Max. Differential Pressure |

Temperature Range |

Standard Connection Size |

Optional Connection Size |

Max. Speed |

| GPM |

M³/hr |

Gallons / 100 rev |

Liters / rev |

PSI |

Bar |

°F |

°C |

in. |

mm |

in. |

mm |

Rev / min |

| ZP1 6 |

6.0 |

1.3 |

0.8 |

0.030 |

200 |

14 |

-40° to 300° |

-40° to 150° |

1½" |

40 |

1" |

25 |

800 |

| ZP1 15 |

9.0 |

2.0 |

1.4 |

0.052 |

200 |

14 |

-40° to 300° |

-40° to 150° |

1½" |

40 |

- |

- |

700 |

| ZP1 18 |

17.0 |

3.8 |

3.0 |

0.110 |

200 |

14 |

-40° to 300° |

-40° to 150° |

1½" |

40 |

2" |

50 |

600 |

| ZP1 30 |

36.0 |

8.2 |

6.0 |

0.230 |

200 |

14 |

-40° to 300° |

-40° to 150° |

1½" |

40 |

2" |

50 |

600 |

| ZP1 60 |

90.0 |

20.4 |

15.0 |

0.580 |

200 |

14 |

-40° to 300° |

-40° to 150° |

2½" |

65 |

3" |

80 |

600 |

| ZP1 130 |

150.0 |

34.1 |

25.0 |

0.960 |

200 |

14 |

-40° to 300° |

-40° to 150° |

3.0 |

80 |

4" |

100 |

600 |

| ZP1 180 |

230.0 |

52.2 |

38.0 |

1.450 |

200 |

14 |

-40° to 300° |

-40° to 150° |

4.0 |

100 |

- |

- |

600 |

| ZP1 220 |

310.0 |

70.4 |

52.0 |

1.980 |

200 |

14 |

-40° to 300° |

-40° to 150° |

4.0 |

100 |

- |

- |

600 |

| Model |

Nominal Capacity |

Displacement |

Max. Differential Pressure |

Temperature Range |

Rec. Inlet

(W x L) |

Outlet |

Max. Speed |

| GPM |

M³/hr |

Gallons / 100 rev |

Liters / rev |

PSI |

Bar |

°F |

°C |

in. |

mm |

in. |

mm |

Rev / min |

| ZP1 34 |

24.0 |

5.4 |

6.0 |

0.22 |

200 |

14 |

-40° to 300° |

-40° to 150° |

1.75 x 6.75 |

44.50 x 171.45 |

2" |

50 |

400 |

| ZP1 64 |

60.0 |

13.6 |

15.0 |

0.57 |

200 |

14 |

-40° to 300° |

-40° to 150° |

2.24 x 8.82 |

56.90 x 224.03 |

2½" |

65 |

400 |

| ZP1 134 |

100.0 |

22.7 |

25.0 |

0.96 |

200 |

14 |

-40° to 300° |

-40° to 150° |

2.97 x 9.25 |

75.44 x 234.95 |

3" |

80 |

400 |

| ZP1 224 |

200.0 |

45.4 |

52.0 |

1.97 |

200 |

14 |

-40° to 300° |

-40° to 150° |

3.87 x 11.00 |

98.30 x 279.40 |

4" |

100 |

400 |

| ZP2 Pump Performance |

| Model |

Nominal Capacity |

Displacement |

Max. Differential Pressure |

Temperature Range |

Standard Connection Size |

Optional Connection Size |

Max. Speed |

| GPM |

M³/hr |

Gallons / 100 rev |

Liters / rev |

PSI |

Bar |

°F |

°C |

in. |

mm |

in. |

mm |

Rev / min |

| ZP2 6 |

8.0 |

1.8 |

0.8 |

0.030 |

300 |

21 |

-40° to 200° |

-40° to 93° |

1½" |

40 |

1" |

25 |

800 |

| ZP2 15 |

11.0 |

2.5 |

1.4 |

0.052 |

250 |

17 |

-40° to 200° |

-40° to 93° |

1½" |

40 |

- |

- |

700 |

| ZP2 18 |

20.0 |

4.5 |

3.0 |

0.108 |

200 |

14 |

-40° to 200° |

-40° to 93° |

1½" |

40 |

2" |

50 |

600 |

| ZP2 30 |

36.0 |

8.2 |

6.0 |

0.227 |

250 |

17 |

-40° to 200° |

-40° to 93° |

1½ |

40 |

2" |

50 |

600 |

| ZP2 45 |

58.0 |

13.2 |

10.0 |

0.366 |

450 |

31 |

-40° to 200° |

-40° to 93° |

2" |

50 |

- |

- |

600 |

| ZP2 60 |

90.0 |

20.4 |

15.0 |

0.568 |

300 |

21 |

-40° to 200° |

-40° to 93° |

2½" |

62 |

3" |

80 |

600 |

| ZP2 130 |

150.0 |

34.1 |

25.0 |

0.946 |

200 |

14 |

-40° to 200° |

-40° to 93° |

3" |

80 |

4" |

100 |

600 |

| ZP2 180 |

230.0 |

52.2 |

38.0 |

1.450 |

450 |

31 |

-40° to 200° |

-40° to 93° |

4" |

100 |

- |

- |

600 |

| ZP2 220 |

310.0 |

70.4 |

52.0 |

1.950 |

300 |

21 |

-40° to 200° |

-40° to 93° |

4" |

100 |

- |

- |

600 |

| ZP2 210 |

Available Soon |

| ZP2 320 |

Available Soon |

| ZP2 323 |

Available Soon |

| Model |

Nominal Capacity |

Displacement |

Max. Differential Pressure |

Temperature Range |

Rec. Inlet

(W x L) |

Outlet |

Max. Speed |

| GPM |

M³/hr |

Gallons / 100 rev |

Liters / rev |

PSI |

Bar |

°F |

°C |

in. |

mm |

in. |

mm |

Rev / min |

| ZP2 34 |

24.0 |

5.4 |

6.0 |

0.22 |

250 |

17 |

-40° to 200° |

-40° to 93° |

1.75 x 6.75 |

44.50 x 171.45 |

2" |

50 |

400 |

| ZP2 64 |

60.0 |

13.6 |

15.0 |

0.57 |

300 |

21 |

-40° to 200° |

-40° to 93° |

2.24 x 8.82 |

56.90 x 224.03 |

2½" |

65 |

400 |

| ZP2 134 |

100.0 |

22.7 |

25.0 |

0.96 |

200 |

14 |

-40° to 200° |

-40° to 93° |

2.97 x 9.25 |

75.44 x 234.95 |

3" |

80 |

400 |

| ZP2 224 |

200.0 |

45.4 |

52.0 |

1.97 |

300 |

21 |

-40° to 200° |

-40° to 93° |

3.87 x 11.00 |

98.30 x 279.40 |

4" |

100 |

400 |

|

|

Hours of Operation:

Monday – Friday, 8:30 a.m. – 5 p.m. EST

|

| |