|

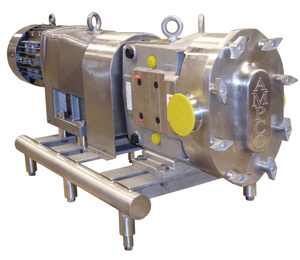

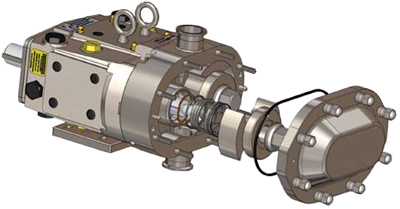

Ampco ZP3 Series Clean-In-Place Circumferential Piston Pump

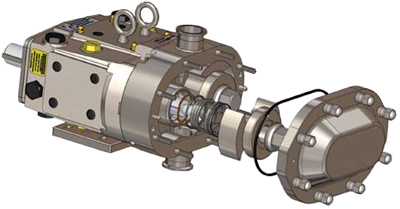

Ampco's ZP3 clean-in-place (CIP) pumps are Ampco's newest. ZP3 CIPs replicate the Universal I & II CIP pumps by Waukesha Cherry Burrell and are completely interchangeable with Waukesha and Wright-Flow pumps, but also contain several upgraded features. ZP3 CIP pumps, like all Ampco pumps, are also designed for maximum service life and reconditionability, and are available with pressure ratings up to 500 psi.

ZP3 Improvements & Advantages:

- Front-Loading Seals located closer to the product flow for ease of maintenance

- In-Line Cleanability without further modifications

- New Rotor Case Design for maximum efficiency

- Tungsten Carbide Seal Faces for longer life

- New pumps can be reconditioned 2 to 3 times

ZP3 CIP Improvements

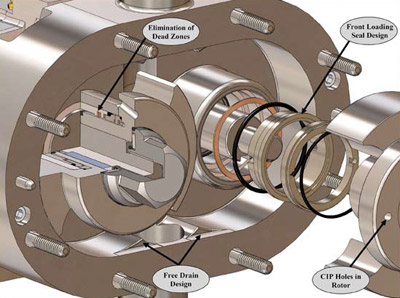

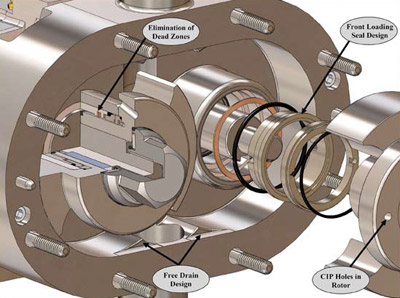

ZP3 Clean-In-Place Enhancements:

- Front-Loading Seals offer improved CIPability with turbulent flow to seal faces

- Elimination of Dead Zones in shaft bore and CIP holes in body hub improve CIPability and efficiency

- Free Drain Design for CIPability and efficiency

- CIP Holes in Rotor ensure turbulent flow to cover hub

- Gear Case & Shafts 100% Interchangeable with Ampco ZP2 pumps

- Existing ZP2 Pumps (and similar competitors' pumps) Upgradeable to ZP3 CIP by fitting new rotors and seals and machining the existing rotor case

Ampco ZP3's Front-Loading Seals

- EHEDG Certified, 3A and ATEX Conformant

- Clean-In-Place Capable

- Purely Mechanical Seal Design

- Interchangeable with Universal I & II pumps by Waukesha Cherry Burrell

- Stainless Steel Gear Case & Bearing Retainer

- Solid Cover Casting

- Helical Gears

- 17-4 Shafts

- O-Ring Seal Cleanout Plugs

- Oil Plug Sight Glass

- Four-Pad Gear Case

- Capacity Range: 0.1 to 310 gpm (0.02 to 70.4 m³/hr)

- Pressure Range: up to 500 psi / 34 bar

- Temperature Range: -40°F tp +300°F (-40°C to +150°C)

Note: Hot clearances required for high-temp operation

- Viscosity Range: 1 to 1,000,000 CPS

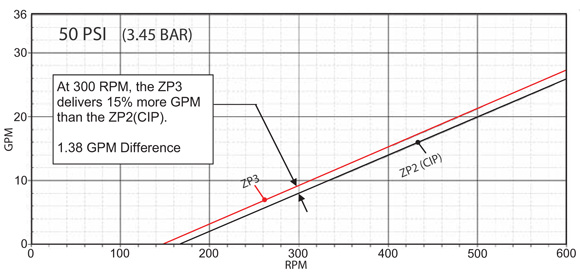

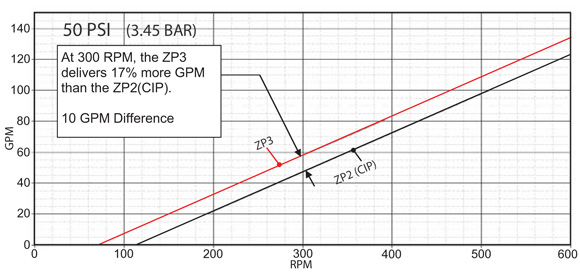

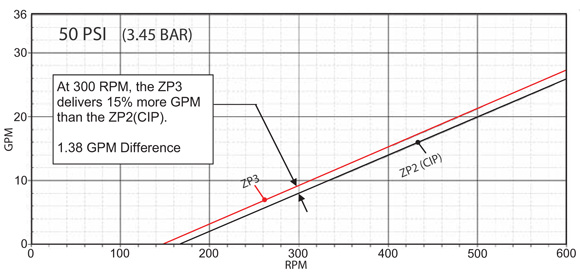

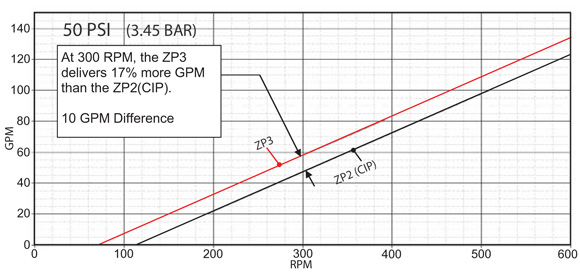

ZP3 Sample Comparison Curves:

|

| Ampco ZP3-30 vs. Ampco ZP2-30 CIP |

|

| Ampco ZP3-130 vs. Ampco ZP2-130 CIP |

ZP CIP Pump's Circumferential Pistons

- Bakery: dough, fats, fruit filling, icing, oils, yeast

- Beverages: beer, fruit concentrate, fruit juices, mash

- Candy: chocolate, cocoa butter, corn syrup, gelatin, sugars

- Canned Foods: baby food, jams, jellies, mayonnaise, potato salad, pudding, relish, stews

- Cosmetics: creams, emulsions, jellies, lotions, shampoo, toothpaste

- Dairy: butter, cream, curds, ice cream, margarine, milk, soft cheese, yogurt

- Dressings: mayonnaise, many other sauces

- Flavorings: concentrates, syrups

- Industrial: auto paint, inks, latex, polymers

- Meats: broth, fats, gelatin, pet foods, sausage fillings

| ZP Series & Competitors Comparison |

| Waukesha Cherry Burrell |

Wright Flow Technologies |

Ampco Pumps |

| Cover Plate / Hubs |

Solid Cover Casting |

Solid Cover Casting |

| Cast Iron Gear Case |

Cast Iron Gear Case |

Stainless Steel Gear Case |

| Two-Part Epoxy Blue Paint |

Powdercoat White Paint |

Electropolish Finish |

| Powder Metal Retainers |

Stainless Steel Retainers |

Stainless Steel Retainers |

| Bi-Metal Shafts |

17-4 ph1150 Shafts |

17-4 ph1150 Shafts |

| Spur Gears |

Helical Gears |

Helical Gears |

| 3-Pad Gear Case |

4-Pad Gear Case |

4-Pad Gear Case |

| 1-Side Grease Zerks |

2-Side Grease Zerks |

2-Side Grease Zerks |

| 3-Wing Wing Nut |

2-Wing Wing Nut |

2-Wing Wing Nut |

| Split Wave Spring |

Solid Wave Spring 17-7 |

Solid Wave Spring 17-7 |

| Standard Lube |

Anti-Microbial Lube |

Anti-Microbial Lube |

| Sight Glass Oil Fill |

6 Oil Fill Plugs |

8 Oil Fill Plugs |

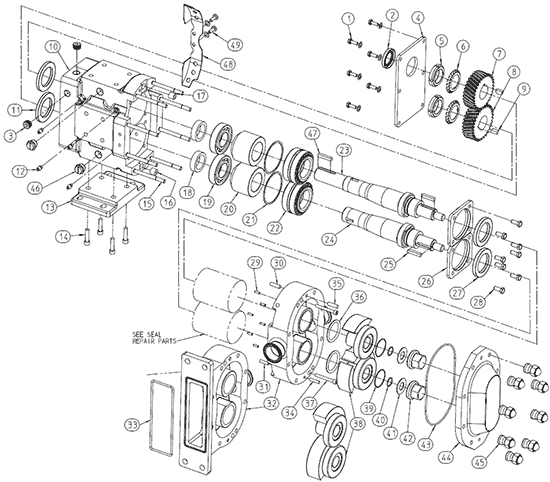

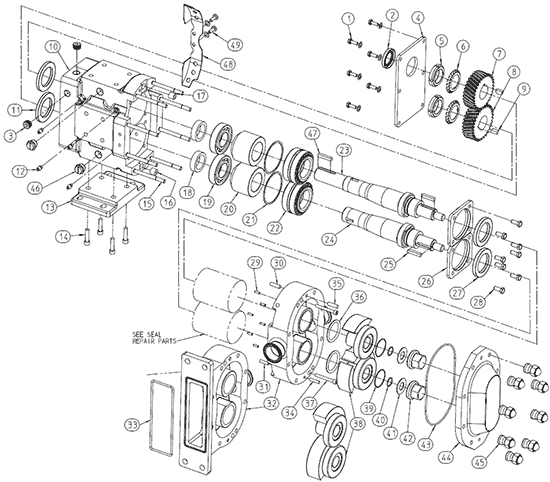

Ampco ZP CIP Pump Parts Diagram

|

|

Hours of Operation:

Monday – Friday, 8:30 a.m. – 5 p.m. EST

|

|